-

Pressing Capability Enables the Production of Cooling Tube Clamping Plates For Heat Exchanger Core »

Date Added: 28/11/2023

We were approached by a company requiring the production of a series of one-piece pressed plates that form part of the clamping and fixing structure for the cooling tube core within a new heat exchanger design. A total of 5 plate types were produced and feature multiple bends at the same pitch...

See Full Story »

-

Bespoke Tension System Components in 431S29 Martensitic Stainless Steel for Offshore Application »

Date Added: 23/10/2023

Brooks Forgings Ltd is one of the world’s leading manufacturers of components used in tensioning and compression systems primarily focusing on the production of non-standards in special materials to customer drawings and design. Our client who is involved in offshore and subsea applications...

See Full Story »

-

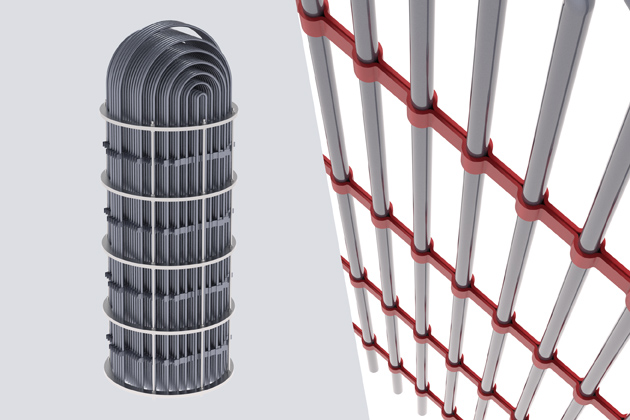

Specialised Bending Capability Enables the Production of U-Bolts in A4-80 Stainless Steel »

Date Added: 24/08/2023

Brooks Forgings was approached by a company requiring the production of 100 quantity bespoke M24 U-bolts in A4-80 stainless steel material. After experiencing failures in the field our customer conducted various mechanical tests and identified that it was a result of a previous supplier using...

See Full Story »

-

Forged Railhead Replication For Partick Pumping Station Restoration Project in Glasgow »

Date Added: 14/06/2023

Brooks Forgings specialise in the replication of decorative ironwork components required for historic restoration projects throughout the UK and beyond. The production of forged railheads is a specific specialty of ours and can be offered as single units or forged directly to the bar in...

See Full Story »

-

Special Forged Eye Bolts in ASTM A320 Grade L7 For Petrochemical Pressure Vessels »

Date Added: 30/05/2023

Brooks Forgings Ltd is one of the world’s leading manufacturers of eye bolts primarily focusing on the production of non-standards in special materials. Eyebolt blanks in common materials are held in stock for rapid conversion to customer requirements. The petrochemical sector demands...

See Full Story »

-

Bespoke Forged Tie Down Anchor Socket Solution for Norfolk Market Town »

Date Added: 16/05/2023

Brooks Forgings specialise in the production of fully bespoke components that are often required to solve a problem when no off-the-shelf solution is available. Norfolk is well known for its various outdoor markets which are typically held weekly and organised by various town councils. An ongoing...

See Full Story »

-

Forged Components For The Union Chain Suspension Bridge Refurbishment Project »

Date Added: 17/04/2023

Brooks Forgings were approached to take part in the Union Chain Suspension Bridge restoration project, focusing on the manufacture of replacement chain rod ends and various supporting walkway components. The Union Chain Bridge located in Northumberland spans the River Tweed connecting the Scottish...

See Full Story »

-

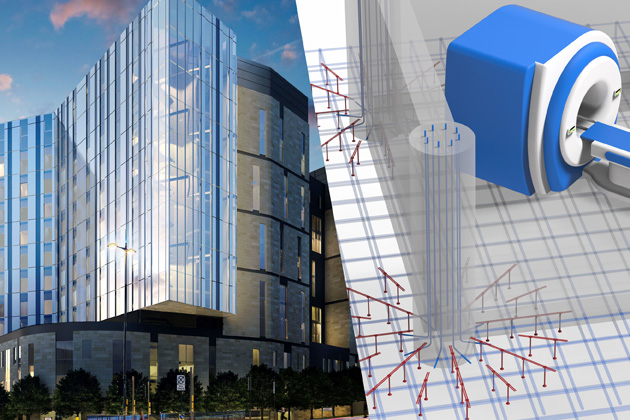

Stainless Steel Punching Shear Solution For Royal Liverpool Hospital MRI Rooms »

Date Added: 08/03/2023

The newly opened state-of-art Royal Liverpool University Hospital is a major teaching and research hospital and the biggest of its kind in the UK. Construction of the New Royal started in 2013 and was originally scheduled to open in 2017 but various engineering concerns and the collapse of...

See Full Story »

-

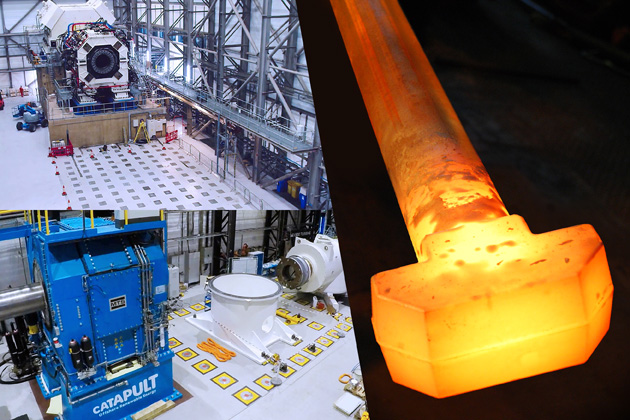

DIN7992 Hammerhead T-Bolts up to M100 x 3100mm for ORE Catapult Research and Testing Facility »

Date Added: 25/01/2023

The National Renewable Energy Centre (now ORE Catapult) is a state-of-the-art facility home to advanced research and testing facilities, primarily for wind and nautical drive trains and blades. The facility based in Blyth, Northumberland, UK was originally constructed as part of an £80m...

See Full Story »

-

Bending Process Expertise Assists with the Production of 65mm Diameter Lifting Lugs »

Date Added: 18/01/2023

Brooks Forgings has become one of the UK’s leading hot and cold benders of raw material, typically diameter, square, and plate sections, forming unconventional shapes used for the production of bespoke components and applications. Our latest bending project required the production of 10...

See Full Story »

-

The Benefits of Single Source Procurement & Multistage Manufacturing From Brooks »

Date Added: 03/01/2023

We have produced a video that demonstrates the benefits of using a single source supplier such as Brooks Forgings for all your component procurement and manufacturing requirements. It is not uncommon for businesses to utilise multiple suppliers to produce single or multiple components for a...

See Full Story »

-

Brooks Forgings Sponsor Mary Stevens Hospice Peter Pan Pantomime 2023 »

Date Added: 02/01/2023

Brooks Forgings is proud to announce that we are one of the main sponsors for the Mary Stevens Hospice 2023 pantomime Peter Pan. By sponsoring the event we can ensure that Mary Stevens has what they need to continue its annual fundraising tradition that is loved by so many in the local community....

See Full Story »