Project in mind?

Please call us now on

+44 (0)1384 563356

Email your enquiry to

sales@brooksforgings.co.uk

Thread rolling is a process that offers increased tensile strength and accuracy with an improved surface finish.

We have made further investment in our machining capacity with the addition of several Thread Rolling machines.

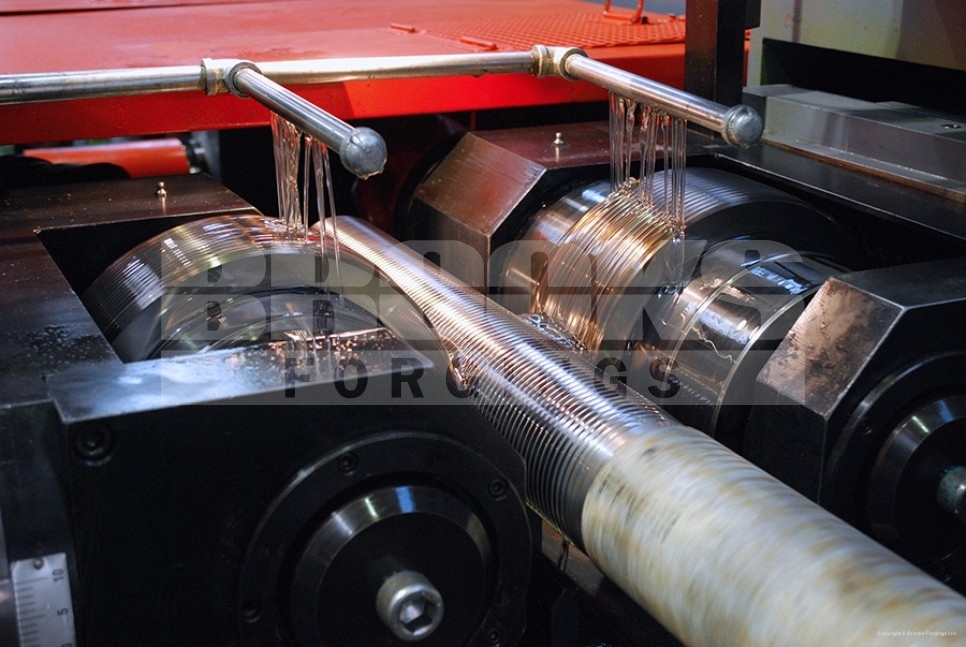

Thread rolling involves the manipulation of raw material by using a pair of rolling dies.

No material is removed during the process and much like forging the raw materials grain is pulled and flows into the thread form to create a stronger thread.

The Thread Rolling process offers:

• High production rate

• No material wastage

• Uniform threads

• Improved physical characteristics

• Greater accuracy

• High level of surface finish

Tensile and Shear Strength

Thread rolling is a cold-forming process and therefore increases the tensile strength.

When compared to screw threading, a process that breaks grain flow (see figure 1), the advantages are immediately clear. The roll threading process manipulates the grain flow, re-forming it in continuous unbroken lines following the contours of the threads (see figure 2).

As a result, shear strength is vastly improved and threads resist ‘stripping’ when in situ because any failures must occur across the diameter rather than with the grain.

Please contact us today to discuss your roll threading requirements.

We can fully manufacture your standard and special fasteners at our factory in the UK.