-

New Fully Automated Flash Butt Welding Machine Increases Capacity »

Date Added: 09/11/2020

The key advantages are the programmable and repeatability of the weld procedure that allows an identical weld to be performed on every component. Job-specific data can be saved in the archive and then recalled at a later date offering full traceability for our Quality Department. This also removes...

See Full Story »

-

Brooks Forgings Sponsor Mary Stevens Hospice Treecycle 2021 »

Date Added: 29/10/2020

Brooks Forgings is proud to announce that we are sponsoring the Mary Stevens Hospice Treecycle 2021. We love a real Christmas tree, but getting rid of them post all of the festive fun can be a nightmare. This is why the Mary Stevens Hospice Treecycle 2021 ensures that you never have to...

See Full Story »

-

Heritage Replication for National Lottery Funded Jewellery Quarter Cemeteries Project »

Date Added: 15/09/2020

Brooks Forgings specialise in the replication of decorative heritage ironwork components. By using a combination of physical original samples, photographs, and the latest digital design software we can create new tooling and reproduce components that are faithful to the original. This service is...

See Full Story »

-

Brooks Forgings Supply Hinkley Point C with Critical Foundation System Components »

Date Added: 27/08/2020

EDF energy, at Hinkley Point C, is building two new nuclear reactors, the first in a new generation of nuclear power stations that will provide low-carbon electricity for up to six million homes. The new reactors will make a significant contribution to the UK’s initiative to reduce carbon...

See Full Story »

-

Brooks Complete Transition from OHSAS 18001 to ISO 45001 with Lloyds Register »

Date Added: 19/08/2020

Brooks Forgings has become one of the first forging companies in the UK to make the transition from the Occupational Health and Safety Management OHSAS 18001 to ISO 45001:2018. A copy of the latest certificate can be downloaded...

See Full Story »

-

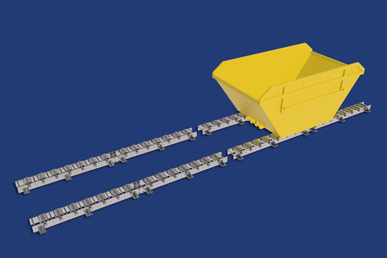

Special Fabrication Keeps Expansion Of Waste Management Facility On Track »

Date Added: 11/06/2020

Brooks Forgings specialise in a diverse range of manufacturing processes and products. This has enabled us to offer bespoke project solutions and meet the specific requirements required by our expanding customer base. Over the last decade, we have grown to be one of the leading suppliers in the...

See Full Story »

-

Temperature Controlled And Programable Bar End Heating Furnaces Installed To Reduce Carbon Footprint. »

Date Added: 14/05/2020

Investment in fully temperature-controlled and programable bar end heating furnaces aims to reduce carbon footprint. Brooks Forgings Ltd has been looking at ways of reducing the consumption of natural gas in its manufacturing processes. By working closely with a company specialising in the design...

See Full Story »

-

Video Conferencing Suite Increases Productivity & Reduces Carbon Footprint »

Date Added: 02/03/2020

The Brooks Engineering Group is now based at several locations throughout the Midlands and deals with an ever-growing global customer base. As part of our Green & Clean Initiative to reduce carbon footprint and goal to improve communication across our group we have invested in a video...

See Full Story »

-

LED Lighting Installed in 7 Bays at Manufacturing Site To Reduce Carbon Footprint »

Date Added: 14/02/2020

Brooks Forgings is proactively researching ways to monitor, evaluate, and reduce energy consumption by utilising the latest and most effective technology available in the marketplace. This is in conjunction with our Green & Clean Initiative to reduce carbon footprint and Lloyds ISO 14001...

See Full Story »

-

Bespoke Tension System Components - The Non Standard Specialists »

Date Added: 03/02/2020

Brooks Forgings specialise in the production of non-standard components that are not readily available off the shelf. We are heavily involved in the construction industry and are able to offer bespoke solutions. A recent project required a special tensioning system to fit a unique application....

See Full Story »