Brooks Forgings Supply Hinkley Point C with Critical Foundation System Components

EDF energy, at Hinkley Point C, is building two new nuclear reactors, the first in a new generation of nuclear power stations that will provide low-carbon electricity for up to six million homes. The new reactors will make a significant contribution to the UK’s initiative to reduce carbon emissions.

One of the main contractors for the project awarded Brooks Forgings with the contract to manufacture and supply a range of foundation bolting assemblies for critical groundworks, in preparation for the installation of various critical infrastructure systems on the Hinkley Point C project.

Believed to be amongst the first British manufactured fastening components supplied into the project, the bolting assemblies utilise the removable DIN 7992 hammerhead t-bolt design, of which Brooks Forgings are the only British manufacturer. Ranging from M24 up to M48 in varying lengths, the bolts locate into a fabricated tube assembly that is welded to BS EN 1090 execution class 2.

Nuclear safety is a priority and extensive quality certification and documentation were required. This included but was not limited to positive material identification (PMI), ultrasonic testing (UT), magnetic particle inspection (MPI), and full mechanicals including tensile, charpy impact tests. This was backed up by an on-site audit that required all documentation and finished components to be made available for inspection.

A total of 5 quality reports were compiled, one for each size/type of foundation bolt assembly. Totalling over 200 pages each, a physical copy was supplied along with fully searchable and bookmarked PDF files to assist in locating critical information swiftly if required.

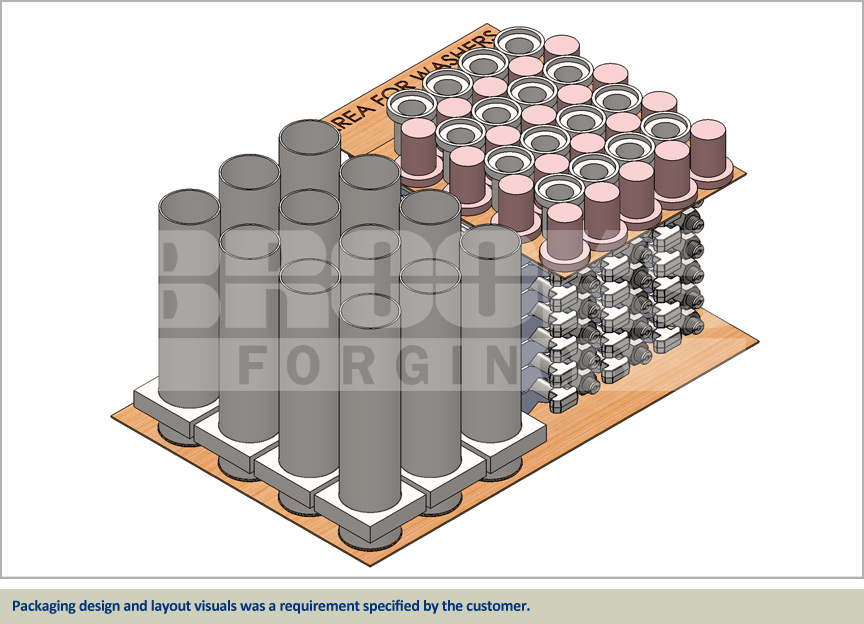

Another unique aspect of the supply was the stringent packaging requirements. Supplied in FSC and ISPM15 compliant wooden packing crates, the components were not allowed to make physical contact with the wood during transit. To prevent this and minimise rust generation during storage, special Vapour Corrosion Inhibitor (VCI) bags were used to line the interior of the wooden boxes. A full packing procedure, 3D rendered component layout, and packing list for each box was designed by Brooks and supplied for approval.

The advantages of dealing with one manufacturer are evident throughout this project. By having in-house forging, machining, and fabrication capability that is approved to EN15048 and EN1090 execution class 3 we have complete control of production and can ensure all components meet the strict quality, testing, and traceability requirements specified.

_thumb__2201243109_m.jpg)

_thumb__2201243409_m.jpg)