Project in mind?

Please call us now on

+44 (0)1384 563356

Email your enquiry to

sales@brooksforgings.co.uk

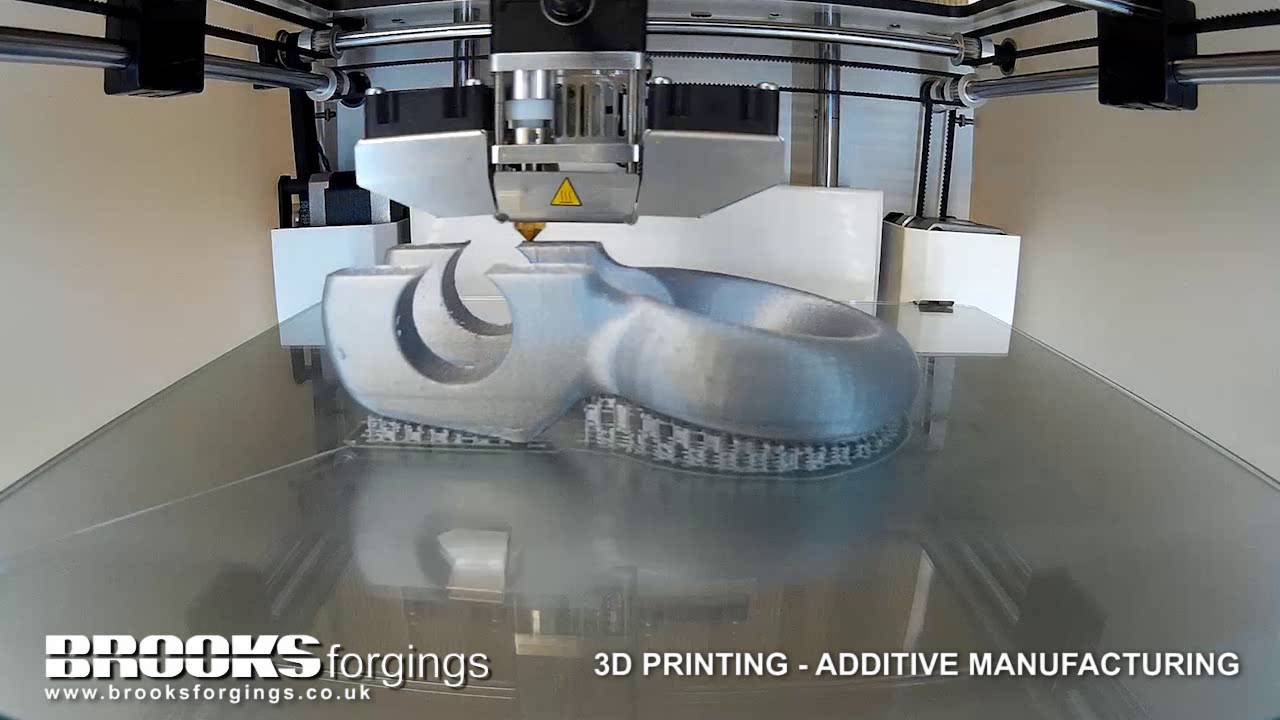

Low-cost production of prototype parts with incredible detail and accuracy.

Our skilled engineers have access to the latest CAD/CAM software used in the industry.

This enables us to produce 3D models and drawings of the highest standard.

The benefits of the process are clear in the early stages of product development as the digital 3D models enable us to offer a range of sample production options. These range from low-cost 3D prints to higher-cost samples from production tooling.

Whatever the option, having a physical and dimensionally accurate component that is representational of either its forged or machined state allows our client to implement it into a sub-assembly for final suitability testing and dimensional checks.

Forging is an industry with high outlay costs. Production of tooling and purchase of raw materials often reaches in excess of £20,000. Our sampling methods can help avoid costly mistakes caused by the production of incorrect dies and scrap material.

Plastic, Resin, and Metal Sampling from Digital Models.

PLASTIC

We have on-site 3D printing capability.

Models can be printed in PLA or ABS plastic and are produced with a solid outer layer and honeycomb inner structure. This process is ideal for dimensional checks or test fit scenarios.

RESIN

In some cases, a solid model is required. This is typical of a forging requirement that will be machine-finished. A block of resin can be CNC machined to represent a forged blank or close net shape. This can be supplied to the customer and test machined to final tolerances.

METAL

If the component does not require a forging process it is sometimes viable and more cost-effective to manufacture an actual physical sample that would be reflective of the final component.