Project in mind?

Please call us now on

+44 (0)1384 563356

Email your enquiry to

sales@brooksforgings.co.uk

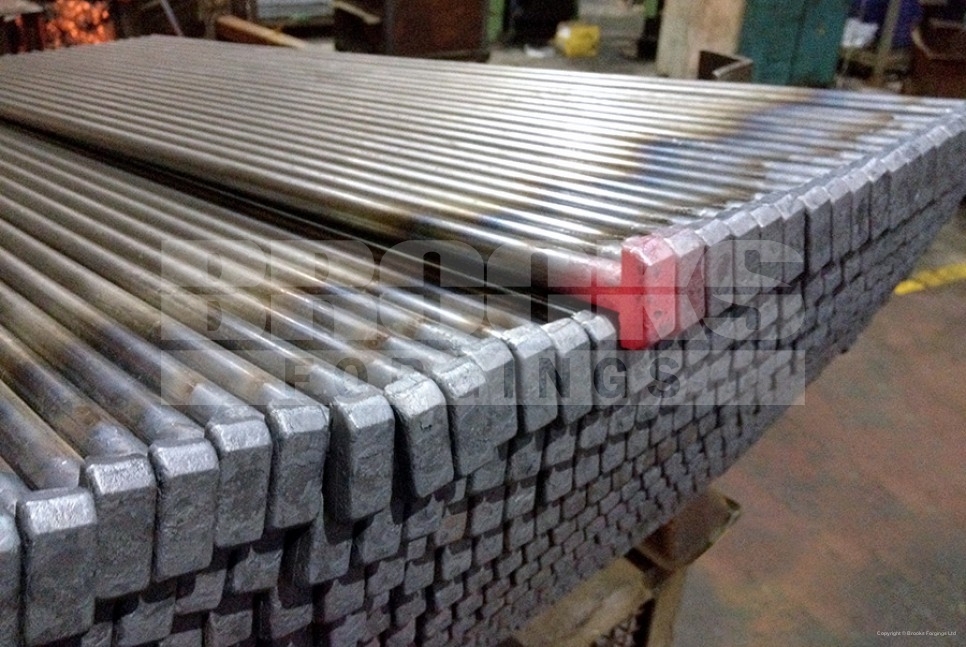

British Made Hammerhead T Bolts to

DIN 261, DIN 7992, and SN425 for use in heavy industrial projects all over the globe.

Brooks Forgings is a leading UK manufacturer of Hammerhead T-Bolts that adhere to DIN 261, DIN 7992, and SN425 standards.

Our bolts are available in sizes ranging from M24 up to M100 and lengths of up to 6000 mm.

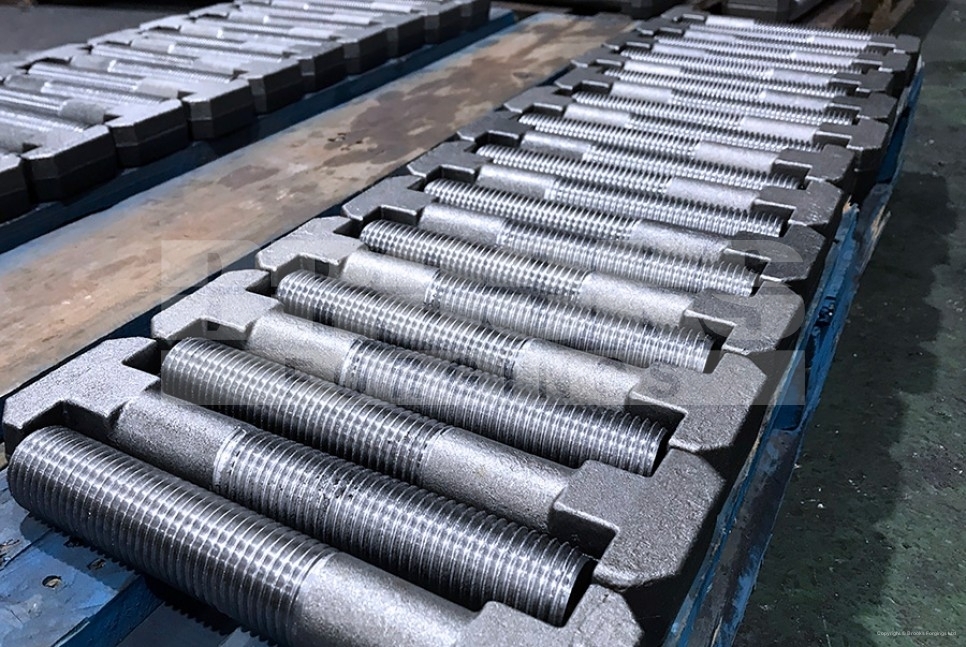

Specifically engineered for heavy industrial applications, T-Bolts are commonly used with a fixed foundation tube assembly. The overall design provides a unique removable foundation system; once installed, the higher-cost bolts can be easily removed for inspection, replaced if necessary, or relocated and reused if the equipment is relocated. The lower-cost foundation tube assembly remains.

Our extensive in-house manufacturing capabilities allow us to quickly produce Hammerhead T-Bolts to meet specific standards or bespoke designs using new production tooling.

Fully removable foundation system

Hammerhead T-Bolts are designed to be used in conjunction with a fixed tube assembly that enables a fully removable bolting solution. Once installed, the bolts can be removed for inspection, replaced if required, or simply relocated and reused if the equipment moves site. The relatively low-cost tube fabrication remains in place and the high-cost bolt is removable.

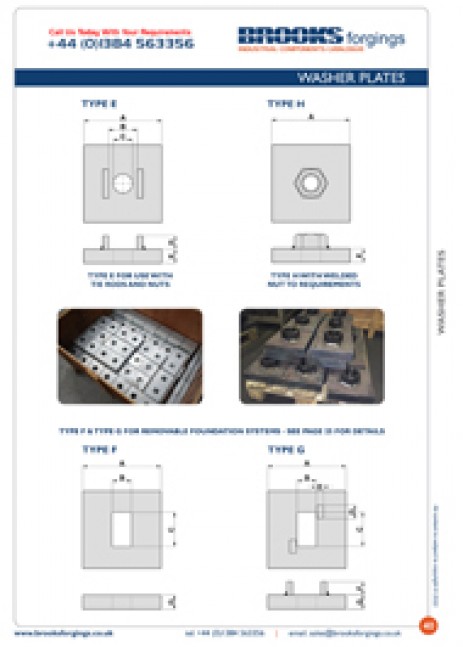

1. Welded tube assembly.

2. Hammerhead T-Bolt.

3. Hammerhead T-Bolt assembly.

4. The hammerhead t-bolt is inserted into the welded tube assembly that has already been set in concrete. The head passes through the slot in the washer plate and the slot at the end of the threaded shank indicates the position of the head.

5. Once the head is past the slot it is rotated through 90 degrees and pulled upwards. This also locates the head between the lugs inside the tube assembly that prevents rotation during the tensioning of the bolt.