Project in mind?

Please call us now on

+44 (0)1384 563356

Email your enquiry to

sales@brooksforgings.co.uk

Electrical Upset Forging is the latest addition to our manufacturing range, further increasing our forging capacity at our UK-based facility.

Brooks Forgings are specialists in the production of upset forged components, with extensive capability. Through further investment, we have now added electrical upset forging to our manufacturing range.

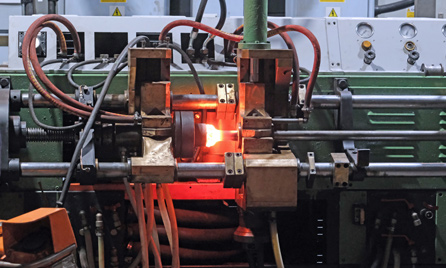

The fully refurbished machine is now commissioned and operational at our Lye, Stourbridge site.

The machine was acquired from the Tinsley Bridge Group, the last of their remaining upset forging capability. It was primarily used for torsion and anti-roll bar production, for which Brooks Forgings is already well-known and a prominent market leader in UK manufacturing.

The Electrical Upset Forging Process

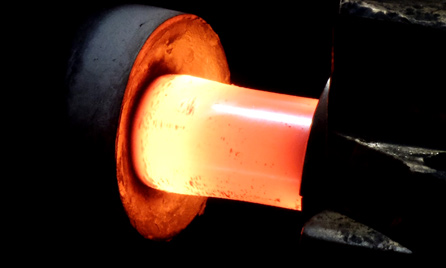

Electrical Upset Forging is a process that uses both electrical resistance heating and hydraulic pressure to produce a large gathering of material from a single heat, at the end of a relatively small diameter bar.

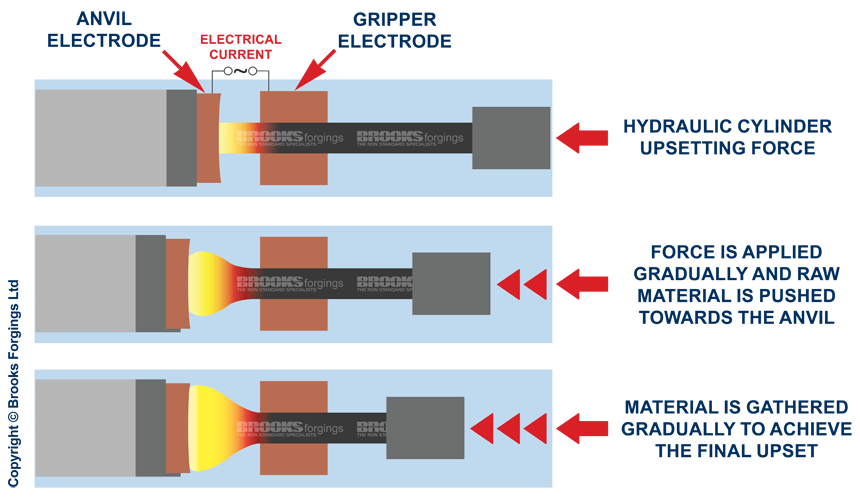

The process begins by clamping the workpiece in the 'gripper' and applying an opposing compressive force to the other end using a hydraulic cylinder.

When the bar makes contact with the 'avil', this completes the electrical circuit, putting a high-amperage, low-voltage current between the anvil eletrode and gripper electrode which is the portion of the bar that will be upset. The electrical resistance within the metal causes rapid, localised resistive heating in the targeted section, bringing it quickly to forging temperature.

The bar is then driven into the anvil using a controlled hydraulic force, gradually upsetting (gathering) the material. The anvil tool can be customised, shaped to create a more defined shape if required. By manipulating the amount of force, the position of the anvil, it is possible to control the amount of gather and its length to create a wide range of forms.

The starting raw material can be up to 60mm in diameter, using metals with exceptional electrical conductivity, such as steel, stainless steel, and exotics.

Benefits and Advantages Of Electrical Upset Forging

The primary benefit of electrical upset forging is its ability to create a precise, controlled mass of material where it's needed, often at the ends of a long component.

In general, the upset forging process is inherently material-efficient because it uses the existing material of the bar stock, minimising scrap compared to machining down a larger diameter bar. Furthermore, the forging action refines the metal's internal grain structure, aligning the grain flow to the contour of the finished part. This results in superior mechanical properties, including increased strength, fatigue resistance, and impact toughness, making the finished part more durable and reliable than one produced by casting or machining alone.

Components Suited To Electrical Upset Forging

Electrical upset forging is ideally suited for manufacturing components that feature a long shank or stem with a larger head or flange at one or both ends. The process excels in industries where high strength, integrity, and mass efficiency are critical. Typical applications include:

Axle Shafts and Drive Shafts: Automotive, military and heavy equipment parts where the end that connects to a wheel or transmission needs a larger diameter.

Engine Valves: Used in internal combustion engines, where a long stem connects to a wide, flat head.

Thermowells: Critical components in the oil and gas industry requiring strong, flanged ends for threading and connection.

Specialist Fasteners: High-performance parts that demand exceptional mechanical properties for reliability under stress.

Computer Controlled & Settings Library

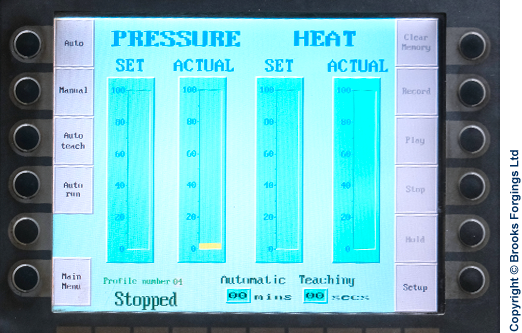

Our electrical upset forging machine has a fully integrated computer system. This enables our operators to create, store, and retrieve specific forging parameters, establishing a comprehensive library for both custom components and standard forms based on material type, length, and diameter.

This system ensures full repeatability, allowing less experienced operators to use the machine with minimal training.

Reduced Carbon Footprint & Solar Power Access

When using electrical upset forging, the carbon footprint per component is significantly reduced because only the necessary amount of energy is consumed, in contrast to the continuous oil or gas-heated furnaces typically used in conventional upset forging processes.

As part of our Green and Clean Initiative, Brooks Forgings has invested in solar power across all of our sites. The electrical upset forging process can utilise this renewable energy source, further decreasing our carbon footprint.