Project in mind?

Please call us now on

+44 (0)1384 563356

Email your enquiry to

sales@brooksforgings.co.uk

A leading UK producer of Standard and Bespoke Eyebolts, Eyenuts, and Lifting Devices.

Sizes Ranging from M6 to M100 (1/4” to 4”)

Blanks held in stock for rapid conversion

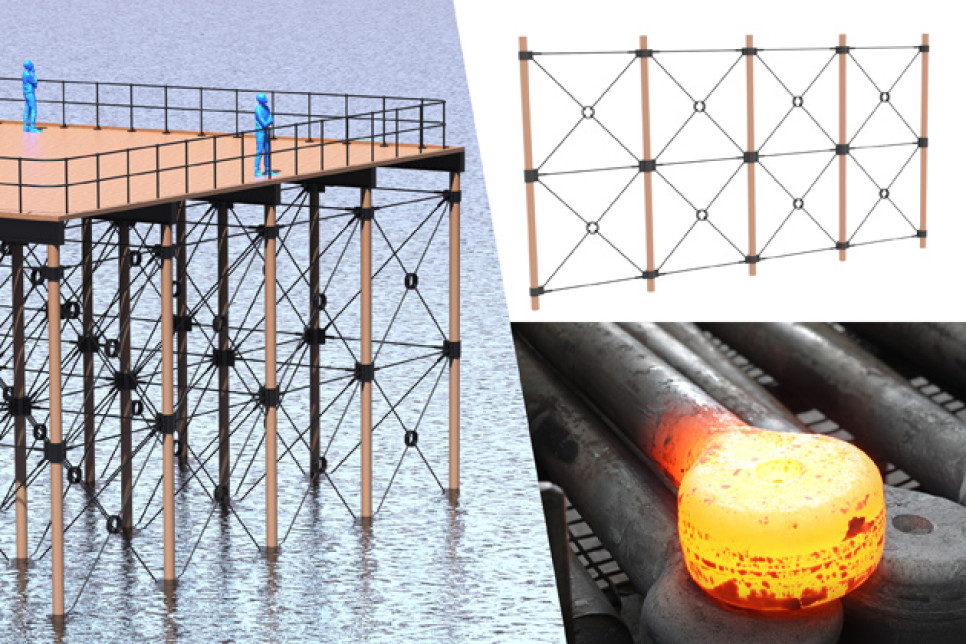

Brooks Forgings is a world-leading British manufacturer of high-quality eye bolts, eye nuts, and lifting eyes. Leveraging over 60 years of expertise and advanced upset and drop forging processes, we produce an extensive range of standard and bespoke components ranging from M6 to M100, ensuring superior grain flow for maximum resilience and safety.

With a comprehensive stock of blanks for rapid conversion and global shipping, we provide solutions for critical lifting and fastening applications across diverse industries.

We have accumulated an extensive range of forging tools for many standard eye bolt and eye nut forms. If one of our stocked blanks isn’t suitable, we can often forge components to specific requirements if the required quantity is viable for production.

Aligned Grain Flow Explained

Forged Bar:

Directional alignment through the forging process has been deliberately oriented in a direction requiring maximum strength. This also yields ductility and resistance to impact and fatigue.

Machined Bar:

Unidirectional grain flow has been cut when changing contour, exposing grain ends. This renders the material more liable to fatigue and more sensitive to stress corrosion cracking.

Cast Bar:

No grain flow or directional strength is achieved through the casting process.

For safety-critical components, such as eye bolts, forging should always be the manufacturing process of choice. It is the only process that compresses and aligns the grain flow to achieve the strongest possible component, extending service life and reducing losses due to downtime or failures in the field.

Eye Bolt blanks held in stock for rapid conversion

Brooks Forgings has been producing eye bolts and eye nuts for over 60 years, supplying many industries all over the globe. We have the knowledge, experience, and manufacturing capability to produce standard and fully bespoke components to suit individual requirements.

A comprehensive range of forged eye bolt blanks are held in stock, and available for rapid conversion to suit urgent requirements.

We have accumulated an extensive range of forging tools for many standard eye bolt and eye nut forms. If one of our stocked blanks isn’t suitable, we can often forge components to specific requirements if the required quantity is viable for production.

Our Eye Bolt & Eye Nut Range Includes

|

|

Manufactured in a range of materials including

|

|

Thread forms include

|

|

Finishes & Coatings include

|

|