Project in mind?

Please call us now on

+44 (0)1384 563356

Email your enquiry to

sales@brooksforgings.co.uk

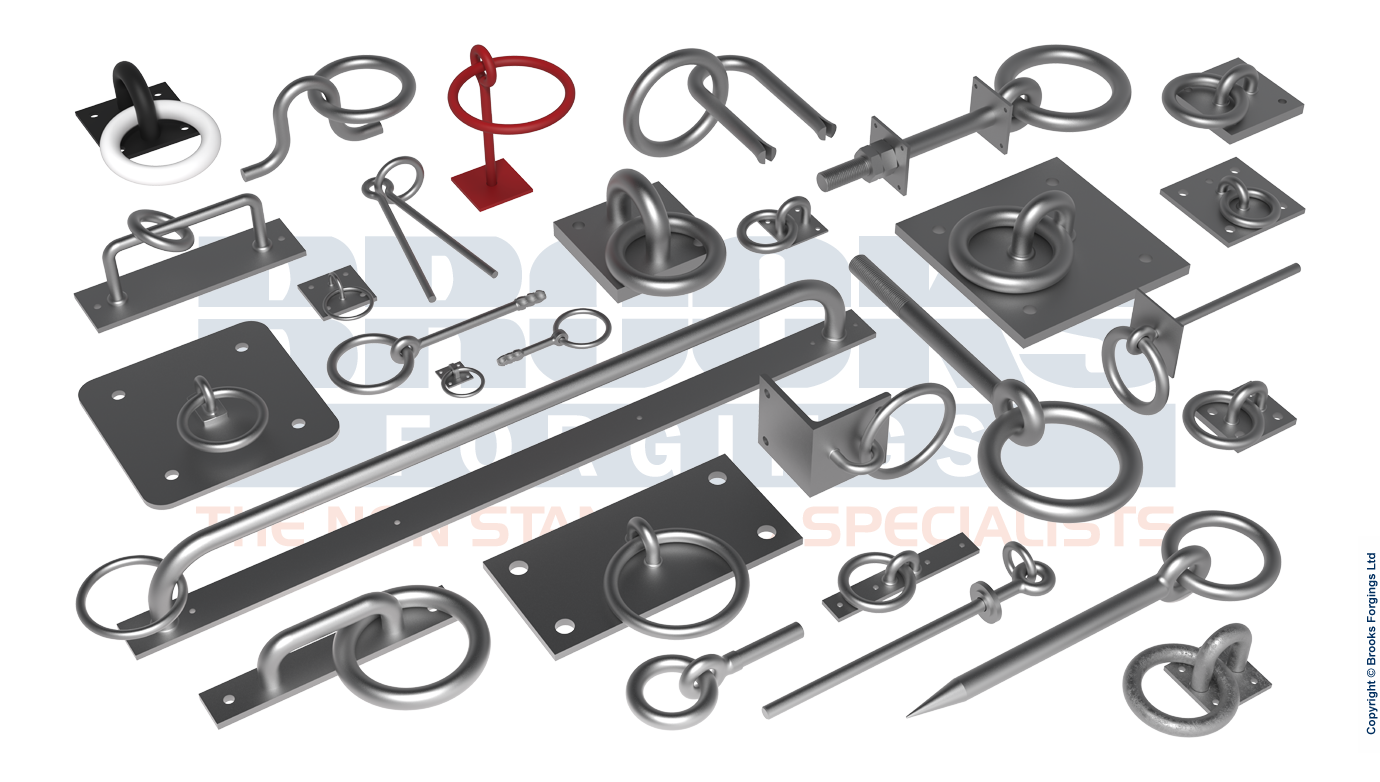

We can manufacture any variation of Mooring Ring to suit customer requirements.

Brooks Forgings specialises in manufacturing a diverse range of high-quality mooring rings, custom-engineered to meet specific customer requirements for the maritime sector.

With our comprehensive in-house capabilities such as heavy bending, ring forming, and flash butt welding, we are able to offer complex mooring solutions for critical maritime applications in a wide range of materials, including stainless steel.

Our experience and expertise are recognised in the industry and we are a specified supplier throughout the marine and dockside sector.

A specified manufacturer and supplier of Mooring Rings throughout the Marine Sector.

Stress Analysis

We have software that can perform Stress Analysis tests from rendered 3D models, using both static and assembled components.

This enables us to evaluate product structure and design suitability and make alterations to suit various requirements. We can also input various material properties making the system fully customisable.

Robot Welding

We have full on-site fabrication and welding capabilities, including Robot Welding.

5 Panasonic Robot Welding Cells Now Online

The advantages of robot welding:

• Faster welding cycle times

• No breaks in production

• Better quality welded product

• Less wasted material

• Consistent weld seam

• Higher precision, flexibility to reach hard-to-reach spots

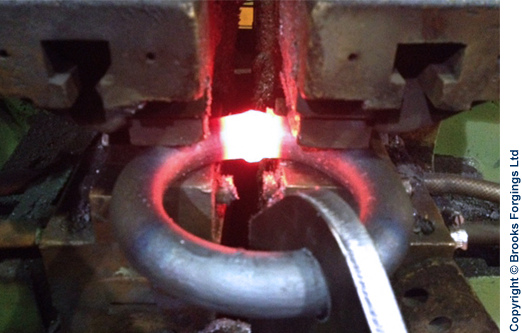

Flash Butt Welding

Our machines have a capacity of 6mm – 60mm in either square or round material. The main advantages of Flash Butt welding are the speed and the overall strength of the process, there is no foreign weld material used meaning the product can be heat treated afterward further increasing tensile strength.

Capacity of 6mm – 60mm in Square or Round Material

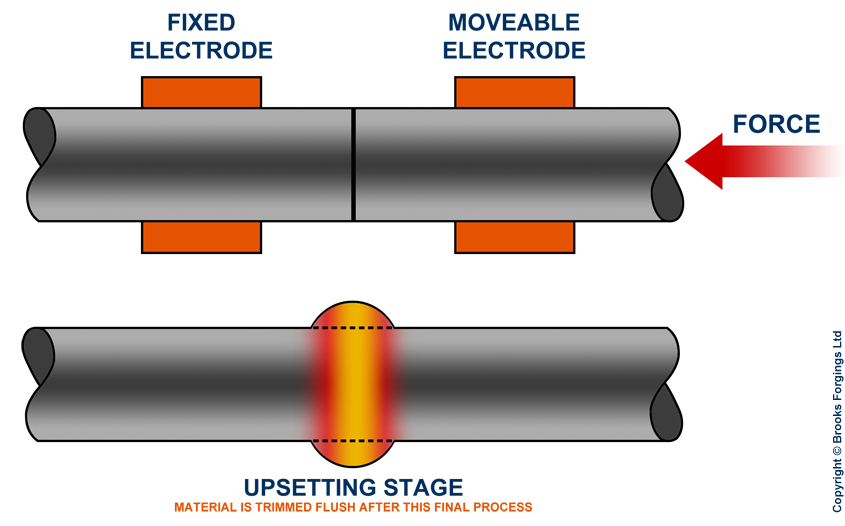

The Flash Butt Welding Process

A process where the surfaces of the workpieces are positioned end to end and are then electronically charged, producing an electric arc that melts and welds the ends of the segments.

Flash Butt Welding is typically divided into 3 stages:

• Preheating

• Flashing

• Upsetting

Preheating is carried out under low welding pressure. Once the welding joint is heated, flashing commences.

The joint surface material is burnt off, resulting in an even surface. After arriving at pre-set flashing loss, upsetting commences, resulting in an irregular "fin" on the surface of the upset metal consisting of molten and oxidized material.

50 Tonne Destructive Tensile Testing

We have a Mayes 4 Column Vertical Universal Tensile Testing Machine (500 KN model) installed at our manufacturing facility, enabling us to complete tests in-house.

We are able to conduct tests on separate rings or full mooring ring and chain-link assemblies to establish they will operate within the specified parameters.

This saves valuable time in the manufacturing process and can help reduce lead times.