-

British Production of Super Duplex DIN 261 Hammerhead T-Bolts »

Date Added: 28/11/2022

Brooks Forgings specialise in the production of Hammerhead T-Bolts to DIN 261 and DIN 7992 specification.We hold tooling for all hot forged sizes, made to your exact requirements. We were approached by a client in the early stages of a new subsea project requiring a substantial amount of M48 X...

See Full Story »

-

Brooks Forgings Completes Challenging Production of Hot Formed Ladle Lid Lifting Bridles »

Date Added: 04/11/2022

Brooks Forgings are always thinking outside of the box when it comes to the production of highly specialised components, utilising our years of expertise and comprehensive range of in-house manufacturing processes. Our client approached us regarding the production of a newly designed Ladle Lid...

See Full Story »

-

Flash Butt Welding Trials of New Steel Alloy for Ovako »

Date Added: 19/10/2022

Brooks Forgings is proud to announce a new collaboration with Ovako. Ovako is one of Europe's leading manufacturers of engineering steel and uses a sustainable manufacturing process to produce a range of engineering steels, including bearing applications and manufacturing and transportation...

See Full Story »

-

Rapid Production of Bespoke Tension Systems for Primary School Temporary Roofing Project »

Date Added: 03/10/2022

Producing components on a short lead time is a speciality of Brooks Forgings. Our extensive capacity and range of in-house manufacturing processes allow us to cater to the most urgent of projects. In this case, our customer was responsible for erecting a temporary roofing system for a primary...

See Full Story »

-

New Website Launched With Over 2500 Image Portfolio »

Date Added: 31/08/2022

Brooks Forgings is proud to announce the launch of a newly revised website.We feel that our website is one of the most extensive in the global forging industry, showcasing our comprehensive range of manufacturing processes, products, and the industries we serve with components. One of the biggest...

See Full Story »

-

Hot Bending Capability Assists World’s Largest Cable Laying Vessel »

Date Added: 11/08/2022

Brooks Forgings has the capability to hot bend various materials up to 80mm solid diameter bar and 80mm thick plate. A world-leading engineering firm approached us to assist them with the development and production of chain drive link profiles, used within a capstan to be installed on the...

See Full Story »

-

Specialised Traction Rods Keep Locomotive Refurbishment Project on Track »

Date Added: 16/05/2022

Brooks Forgings has a diverse range of manufacturing capabilities that enables the production of fully bespoke components for many applications worldwide. Throughout our extensive history, we have assisted many restoration projects requiring the resilience and aligned grain flow only found...

See Full Story »

-

Full Steam Ahead with the A1 Steam Locomotive Trust »

Date Added: 01/03/2022

As part of a continued collaboration between Brooks Forgings (Brooks) and our sister company W.H.Tildesley (WHT), we have once again successfully manufactured and supplied a number of forged components known as foundation ring corner blocks to the A1 Steam Locomotive Trust. The team at the A1 Steam...

See Full Story »

-

Investment in New Doosan DNM 5700 Vertical Machining Centre »

Date Added: 04/02/2022

Brooks Forgings has a wealth of manufacturing processes that enable us to service many industries worldwide with standard and fully bespoke components. Many of the processes we offer require the use of custom jigs, fixtures, and tooling. These are designed and produced in-house that offer tighter...

See Full Story »

-

Brooks Forgings Become Main Sponsor For Mary Stevens Hospice Pantomime 2022 »

Date Added: 01/02/2022

Brooks Forgings is proud to announce that we are the main sponsor for the Mary Stevens Hospice 2022 pantomime Snow White And The Seven Dwarfs.By sponsoring the event we are able to ensure that Mary Stevens has what they need to continue its annual fundraising tradition that is loved by so many in...

See Full Story »

-

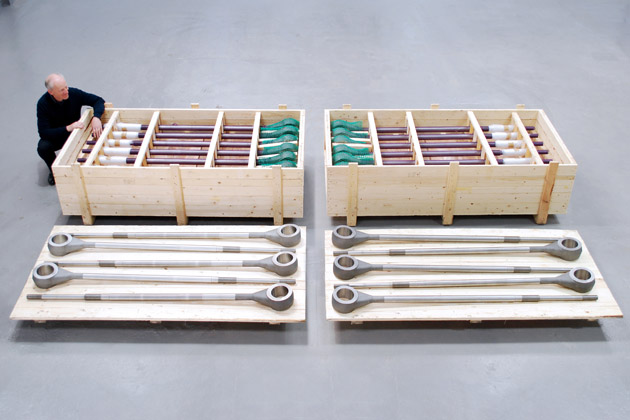

Keeping Tradition Afloat With Bespoke Hand Tools for the British Boat Building Industry »

Date Added: 10/01/2022

By utilising our extensive range of manufacturing processes we can produce many types of bespoke hand tools used within many industries. Our most recent manufacturing project was for a client operating within the British boat-making community, looking to produce a range of specialised hand tools to...

See Full Story »