-

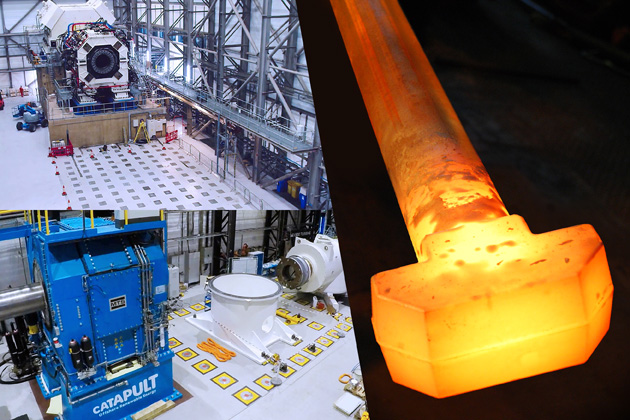

DIN7992 Hammerhead T-Bolts up to M100 x 3100mm for ORE Catapult Research and Testing Facility »

Date Added: 25/01/2023

The National Renewable Energy Centre (now ORE Catapult) is a state-of-the-art facility home to advanced research and testing facilities, primarily for wind and nautical drive trains and blades. The facility based in Blyth, Northumberland, UK was originally constructed as part of an £80m...

See Full Story »

-

Bending Process Expertise Assists with the Production of 65mm Diameter Lifting Lugs »

Date Added: 18/01/2023

Brooks Forgings has become one of the UK’s leading hot and cold benders of raw material, typically diameter, square, and plate sections, forming unconventional shapes used for the production of bespoke components and applications. Our latest bending project required the production of 10...

See Full Story »

-

The Benefits of Single Source Procurement & Multistage Manufacturing From Brooks »

Date Added: 03/01/2023

We have produced a video that demonstrates the benefits of using a single source supplier such as Brooks Forgings for all your component procurement and manufacturing requirements. It is not uncommon for businesses to utilise multiple suppliers to produce single or multiple components for a...

See Full Story »

-

Brooks Forgings Sponsor Mary Stevens Hospice Peter Pan Pantomime 2023 »

Date Added: 02/01/2023

Brooks Forgings is proud to announce that we are one of the main sponsors for the Mary Stevens Hospice 2023 pantomime Peter Pan. By sponsoring the event we can ensure that Mary Stevens has what they need to continue its annual fundraising tradition that is loved by so many in the local community....

See Full Story »

Brooks News

- All News

- 2026 Archive

- 2025 Archive

- 2024 Archive

-

2023 Archive

-

January

- DIN7992 Hammerhead T-Bolts up to M100 x 3100mm for ORE Catapult Research and Testing Facility

- Bending Process Expertise Assists with the Production of 65mm Diameter Lifting Lugs

- The Benefits of Single Source Procurement & Multistage Manufacturing From Brooks

- Brooks Forgings Sponsor Mary Stevens Hospice Peter Pan Pantomime 2023

-

March

-

April

-

May

-

June

-

August

-

October

-

November

-

January

- 2022 Archive

- 2021 Archive

- 2020 Archive

- 2019 Archive

- 2018 Archive

- 2017 Archive

- 2016 Archive

- 2015 Archive

- 2014 Archive

- 2013 Archive

- 2012 Archive

- 2011 Archive

- 2010 Archive

- 2009 Archive

- 2008 Archive