Specialist One Piece Forged Eye Rod Ends For High Performance Jacking Systems

At Brooks Forgings Ltd, we take pride in our expertise in manufacturing high-quality forged eye bolts and eye rods. Our extensive on-site forging and machining capabilities make us an excellent partner for bespoke component production.

In applications requiring high-performance mechanical jacking and power transmission systems, worm or ball screw-driven designs are typically utilised. For low-capacity applications, conventional approaches often involve a fabricated two-piece main rod that includes an eye or clevis end, which may be welded or threaded onto a generic drive shaft. While this method has its applications, it does present potential risks of weld and thread failures in high-capacity scenarios.

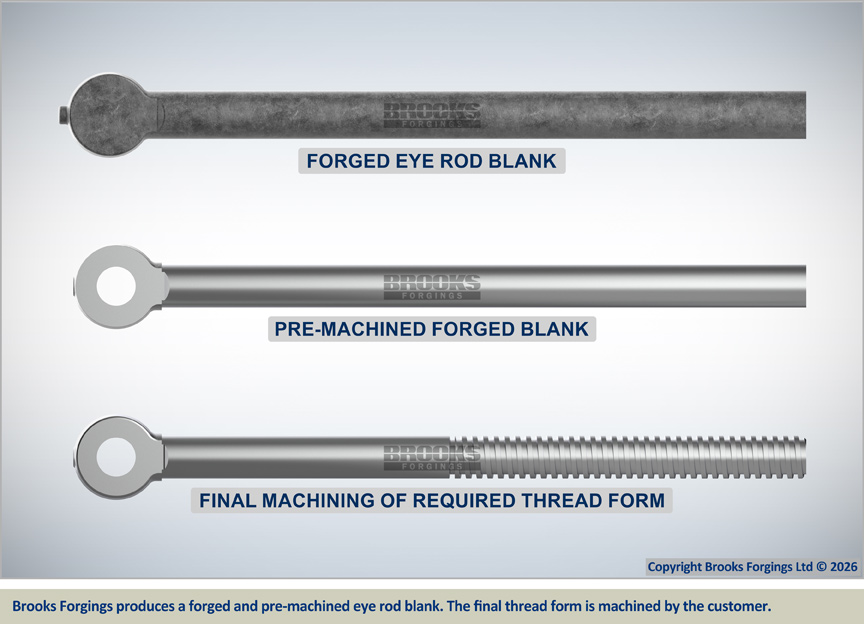

To address this, Brooks Forgings offers superior one-piece forged rod ends that enhance structural integrity through aligned, compressed, and uninterrupted raw material grain flow.

One of our valued returning customers in the actuation and lifting sector has seen significant benefits from this solution, regularly ordering batches of forged one-piece eye rod ends / screws tailored for specialised 15-ton jacking systems.

The forged blanks are produced from 57mm (2.25-inch) diameter 080M40 material using a combination of upset forging and pressing processes. Following this, we ensure quality by shot blasting the raw forgings and conducting independent tensile testing and chemical analysis to ensure the components meet the required standards.

As part of our offer, Brooks Forgings pre-machines the forgings in-house, preparing both the main shaft and centre eye for the end-user's specific needs during their final operations.

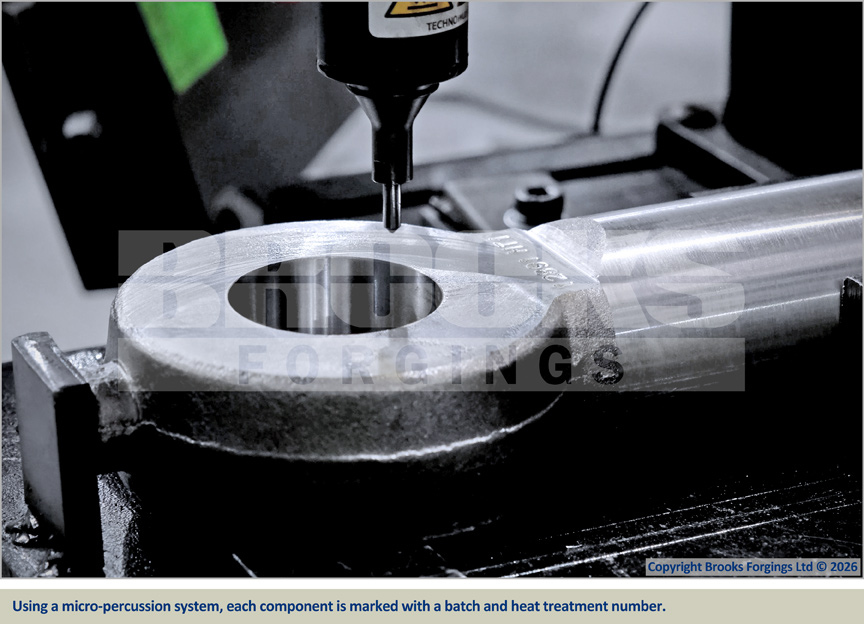

Machined dimensions are inspected using a Marposs Merlin system to ensure all components meet the final requirements and tolerances.

Each component is marked using a micro-percussion system, providing full traceability through its batch and heat treatment number.

To guarantee safe delivery, each part is meticulously wrapped for protection and securely packed in wooden boxes, ensuring that our customer receives their order in optimal condition.

We are dedicated to providing exceptional products and services tailored to the unique requirements of our clients. Please contact us today with your requirements.